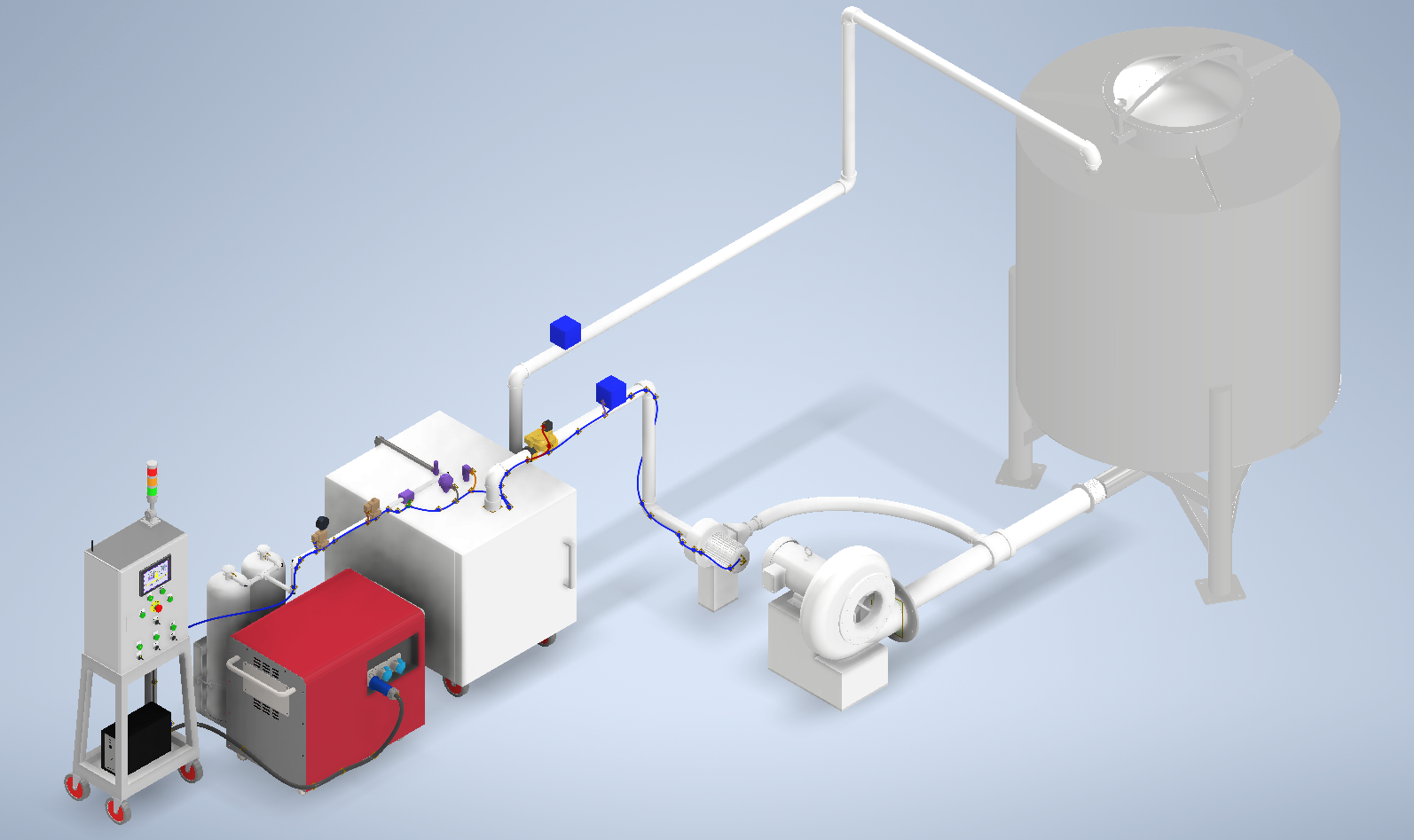

Smart Fumigation System

Smart Fumigation System is designed to make fumigation safer, smarter, and more cost-efficient. It protects fumigators, cargo owners, and the environment by complying with international standards like FAO and OSHA. The system reduces operational costs through automation, while enabling real-time remote monitoring and control over the internet. Every process is logged into permanent records for supply chain traceability, and this data can fuel future AI-driven optimizations. By automatically synchronizing CO₂ supply, phosphine generation, blowers, and backup power, the system ensures seamless and reliable fumigation. For fumigation companies, it not only enhances safety and compliance, but also strengthens brand image, market share, and revenue.

System features

- Hardware and software are modifiable for dry/wet/pure PH₃ fumigation systems

- Materials are chemical-resistant to Phosphine gas

- Automatically injects CO₂ into the Phosphine generator with alert when temperature exceeds 60°C; alarm at 70°C to reduce flammability and explosion risks

- Continuously measures and logs real-time CO₂ flow rate and valve status

- Triggers visual and remote alarms if CO₂ flow rate falls below 0.1 m³/min or exceeds 2.0 m³/min — indicating potential solenoid valve failure, pressure regulator issue, cylinder depletion, line blockage, or breakage

- Resumes previous state or enters safe state upon power recovery, logging any disruptions

- Alerts fumigator via visual and remote notification when Phosphine generator temperature reaches 60°C

- Alerts fumigator when Phosphine generator pressure reaches 10 psig (0.7 bar), requiring manual intervention

- Automatically relieves pressure via mechanical relief valve if pressure reaches 20 psig (1.38 bar) under non- or poorly recirculating conditions

- Real-time monitoring and logging of PH₃ concentration, temperature, and pressure

- Web and mobile interface for remote configuration, control, and monitoring

- Logs and stores data in the cloud: Phosphine generator temperature, pressure, PH₃ flow rate, and PH₃ concentration for traceability

- Modular and scalable system design

- Triggers visual and remote alarm if PH₃ flow rate drops below critical threshold — indicating blockage, leakage, or blower failure

- Automatic switching to backup blower if main blower fails — ensures continuous PH₃ flow and reduces fire/explosion risk

- Detects grid power failure and automatically activates Automatic Transfer Switch (ATS) to start diesel generator within 5 seconds

- Automatically switches back to grid power when stable for 5 seconds

- Monitors ambient conditions: Temperature, Relative Humidity, and CO₂ levels

- Complies with regional safety standards for gas fumigation